The AG 250 and AG 400 municipal spreaders are designed for spreading salt and sand. The structural design of the spreaders enables easy operation and uniform and high-quality spreading of sanding material over the specified width. The spreaders are made of materials that ensure a long service life and optimal performance. The spreader hopper is made of a quality high-density polyethylene. All spreader parts that come into contact with salt and sand are made of stainless steel.

Operation of the spreader

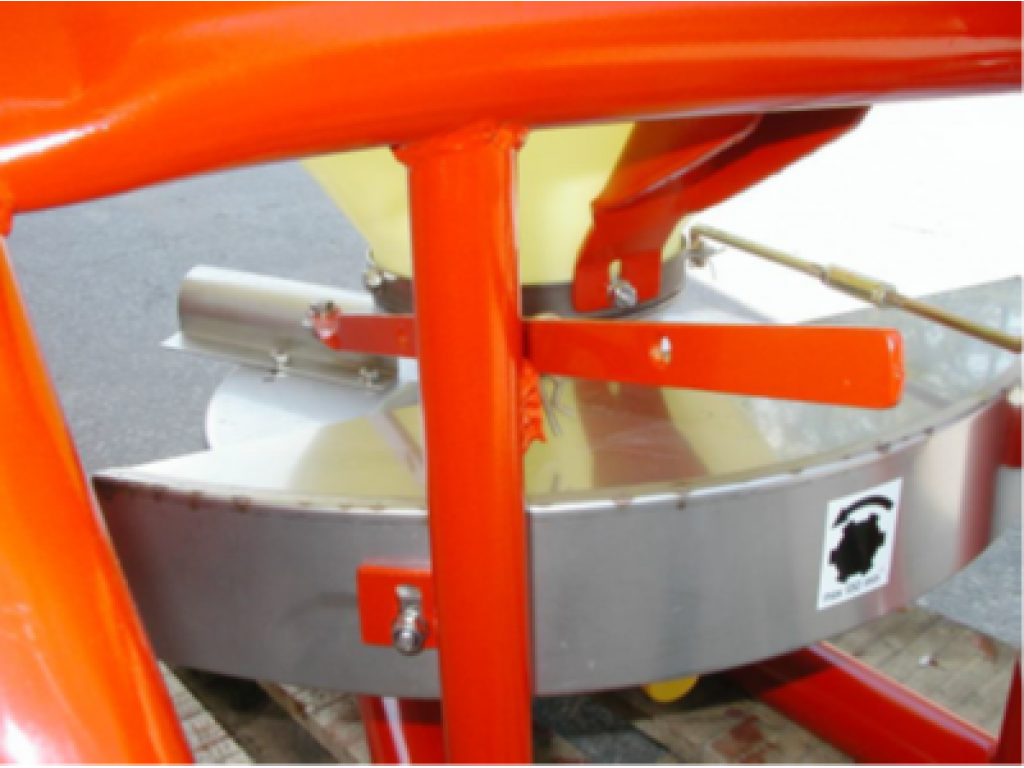

Because the spreader is designed as a tractor implement, it is adapted to be connected to the three-point lifting system of the tractor. The tractor PTO shaft with the angular transmission is connected to the spreader via the universal joint. If the tractor provides additional reinforcement for the lower lifting arms, this will prevent any unwanted lateral oscillations of the spreader, which could affect the driving stability of the tractor. Finally, the spreader is raised to the operating height and adjusted with the central link until it is positioned horizontally. Salt and sand are poured through the two openings at the bottom of the hopper and on the rotating disc with blades, which disperses the material in a uniform fan pattern of a specified discharge width.

A lever with three positions is used to adjust the opening position of the two openings, which also allows for switching between spreading on both sides, only on the left or only on the right side.

The second lever is used to adjust the salt/sand consumption. The blades on the disc can also be adjusted to five different positions which determine the adjustment of the material spreading width. The spreading width also depends on the driving speed, the number of PTO shaft revolutions and the granulation of the sanding material.

Remote control is also available as optional equipment. It is used to control the machine from the tractor cab.

The spreader is easy to maintain. After each use, it should be thoroughly washed with a jet of clean water. At the end of the season, all the moving parts should be greased and oiled. All the frame parts that are not made from stainless steel should be inspected and protected as necessary. A fresh coat of paint should be applied to any larger abrasions.

Optional equipment:

- Remote control kit

- Cover tarp

- Transport signaling equipment

- Cerjak CAT. II. universal joint - 82 cm