Sprayer AGS 3600 - 4200 HP made for high productivity on large surfaces.

The family of quality sprayers for agriculture has been expanded with a new professional AGS HP sprayer with tank capacities from 3600 – 4200 litres. This high-performance sprayer is tailored to the needs of professional users with large surfaces.

Carefully structured with an emphasis on design and useful solutions, these sprayers enable safe and, above all, effective operation on large surfaces. The sectional valve system ensures immediate start of spraying and provides for an even distribution across the entire surface. The parallelogram hitch enables high or low spraying mode which helps to reduce the spray drift. The turning axle improves wheel tracking and protects the crops from trampling. The sprayer can be fitted with air springs that make driving feel more comfortable and with advanced electronic systems that allow automatic boom levelling, automatic adjustment and automatic closing of nozzle sections, as well as automatic wheel turning.

The robust and durable chassis is the result of our extensive experience. Double layer of powder coating ensures the best anti-corrosion protection. The wheel track is continuously adjustable so it can be easily adjusted to different types of crops. All HP sprayers are equipped with mudguards. The chassis also includes a hydraulic support foot for easier connection to the tractor. Using different hitch eyes, the chassis can be connected to the lower or upper tractor hitch.

The robust and durable chassis is the result of our extensive experience. Double layer of powder coating ensures the best anti-corrosion protection. The wheel track is continuously adjustable so it can be easily adjusted to different types of crops. All HP sprayers are equipped with mudguards. The chassis also includes a hydraulic support foot for easier connection to the tractor. Using different hitch eyes, the chassis can be connected to the lower or upper tractor hitch.

They are made from high-quality LDPE. They feature a compact design and excellent mechanical and chemical resistance properties. Their attractive design gives the sprayer its distinctive character. The main tank is available in 3600 and 4200 litre versions. It is designed to provide thorough mixing, minimise residual spray volume and simplify cleaning operations. The sprayers include two additional tanks for washing the circuit and hands.

It is intended for rinsing the main tank and other elements when spraying is finished or interrupted.

The rinsing tank is integrated in the main tank. It can only be filled with clean water. The capacity of the tank is 420l.

It is designed for washing your hands after handling spraying agents. It can only be filled with clean water. The capacity of the tank is 20 l.

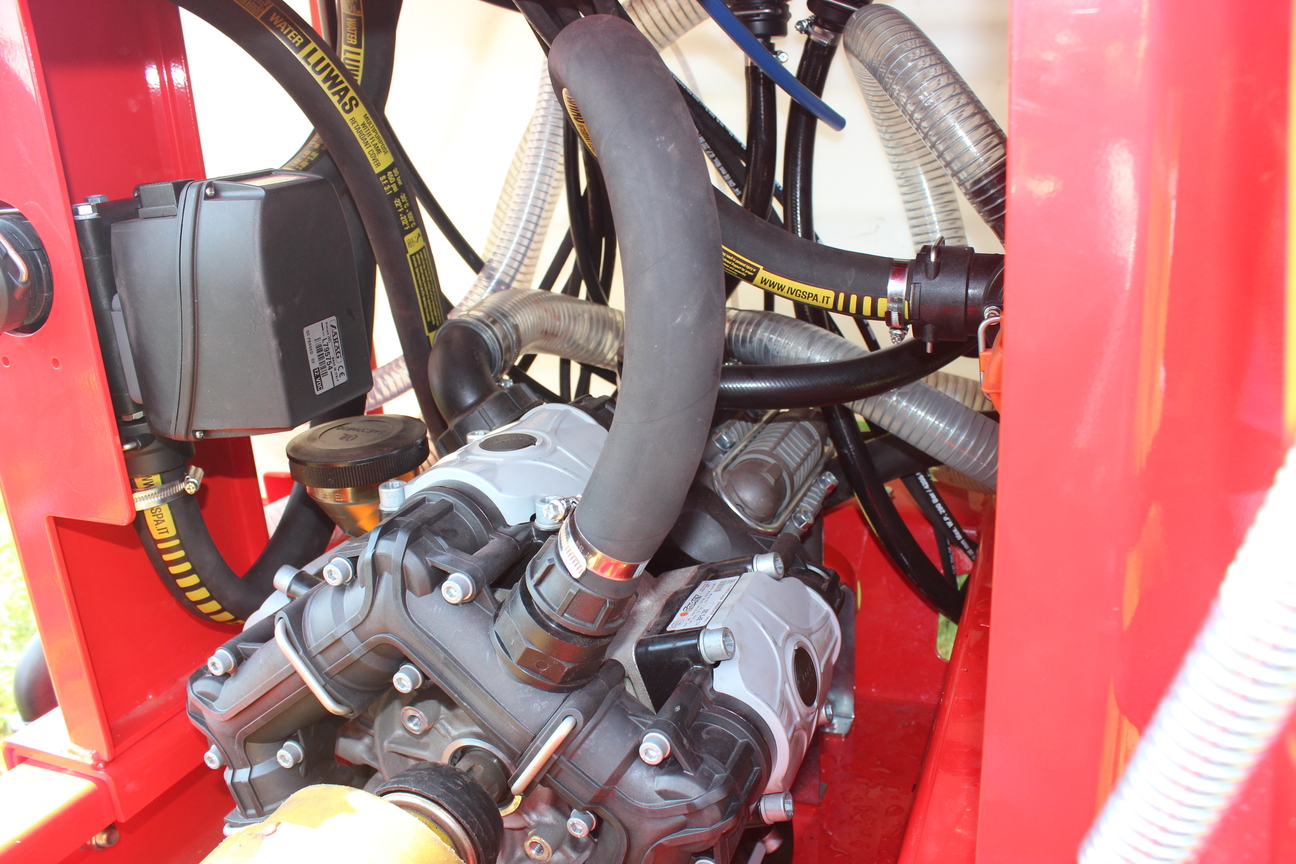

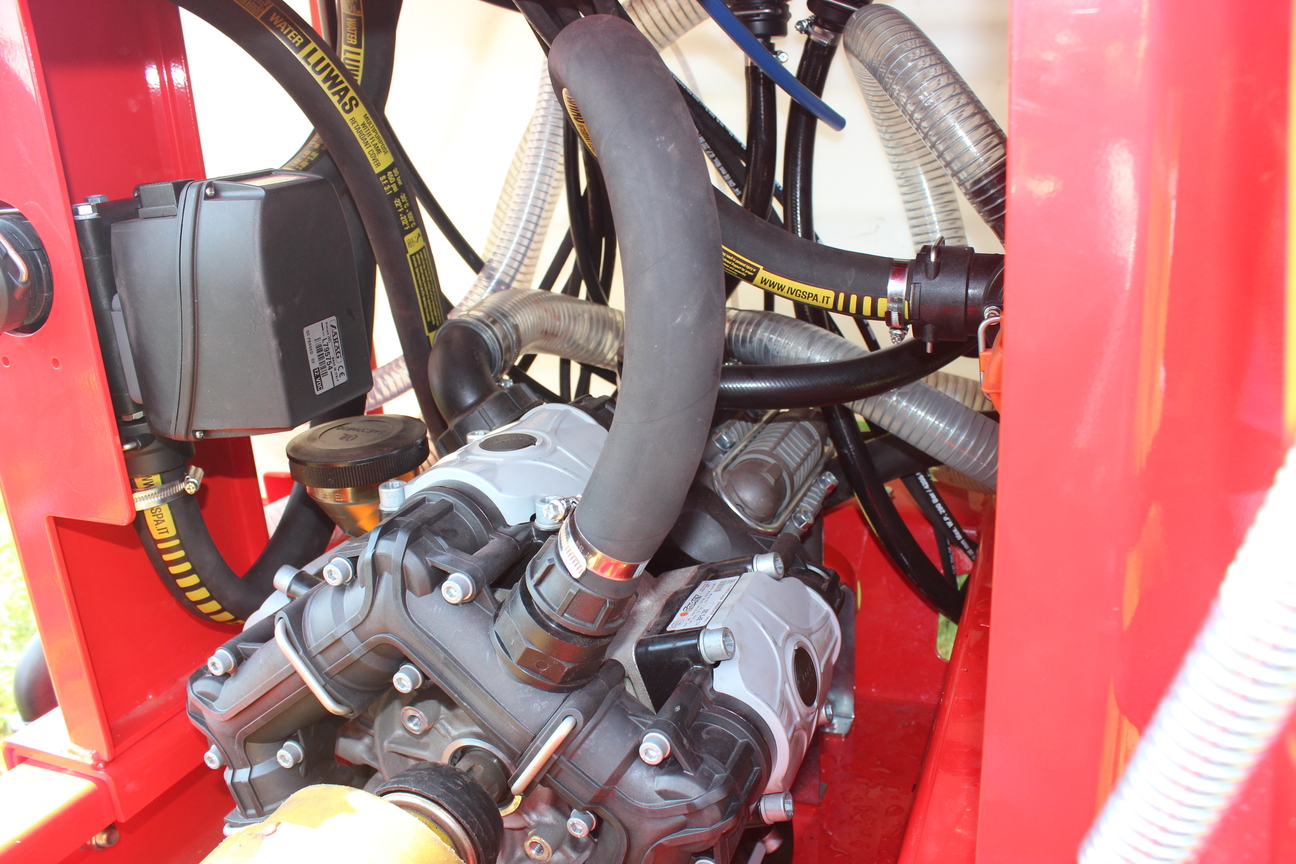

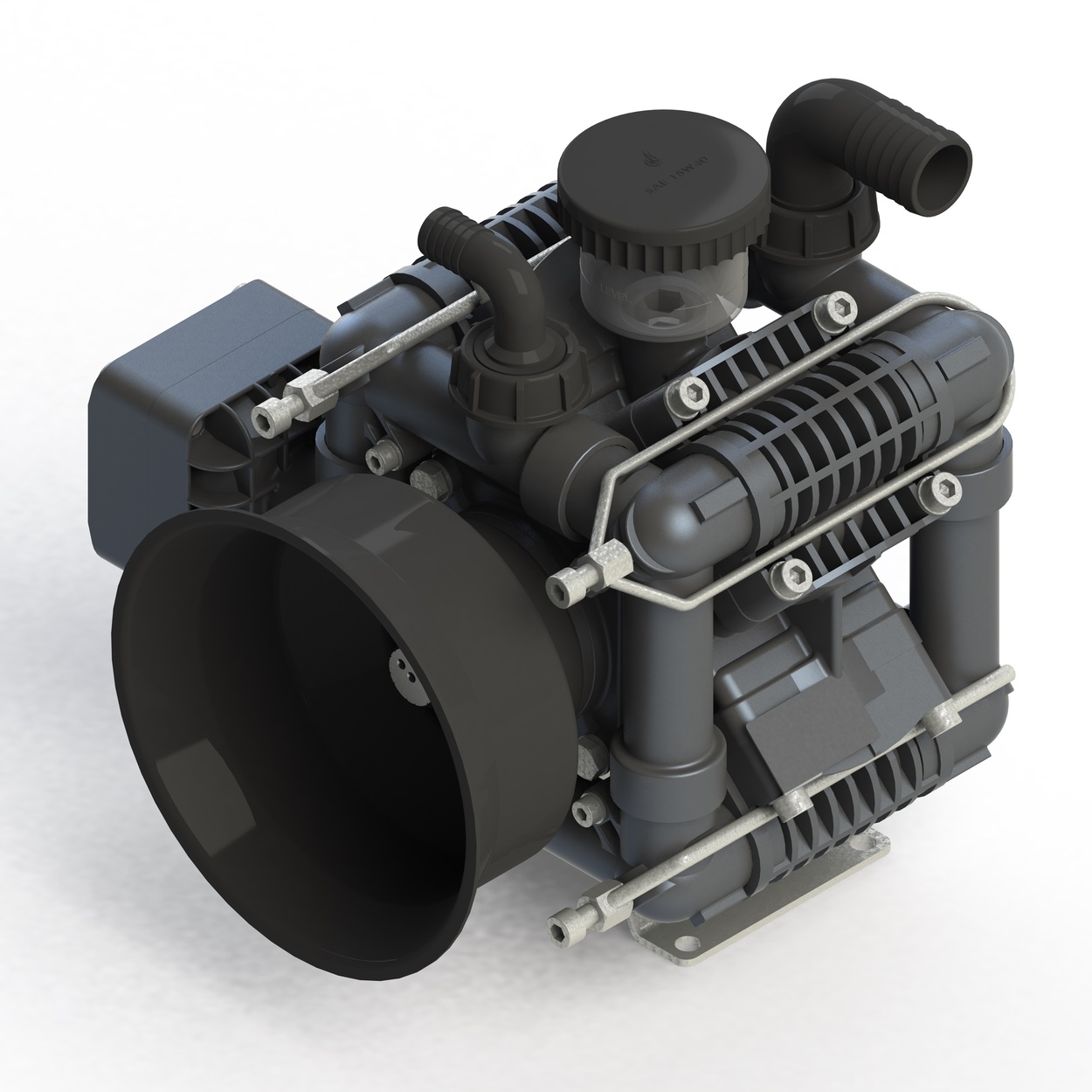

The AGS 3600 – 4200 sprayer is equipped with a system of two piston diaphragm pumps of reputable brands. The first pump, generating a flow of 260 l/min, is used for spraying and the other one with a flow of 150 l/min is used for mixing the spraying agent. The latter enables pressure adjustment for adjusting the mixing intensity, which is very important when liquid fertilizers are used.

The AGS 3600 – 4200 sprayer is equipped with a system of two piston diaphragm pumps of reputable brands. The first pump, generating a flow of 260 l/min, is used for spraying and the other one with a flow of 150 l/min is used for mixing the spraying agent. The latter enables pressure adjustment for adjusting the mixing intensity, which is very important when liquid fertilizers are used.

This prevents the build-up of sediment from powder-based sprays at the bottom of the tank.

Mixing is done by means of the injection nozzle and an independent piston diaphragm pump delivering a flow rate of 150 l/min.

Its advantages are especially revealed when using less soluble powdered spraying agents. The filling container was designed for an efficient preparation and mixing of chemical products. Thanks to the Venturi effect, the spray is easily pumped into the main tank. It provides additional safety when handling chemical products. The filling container also includes a packaging rinser for cleaning the containers of plant protection products, which contains a tip that penetrates the protective film. A convenient mechanism is provided to lower the container to a comfortable height during use.

The sprayer features an external tank filling system for hydrant filling. The system can be used for filling the main tank and the rinsing tank.

The main tank is additionally protected with a non-return valve that prevents the spray from spilling from the tank during filling.

The AGS 3600 – 4200 EN sprayer comes with a new air brake system that adjusts to weight of the sprayer. The heavier the sprayer, the greater the breaking force required. The air brakes ensure additional safety and allow you to achieve higher road speeds. The air brakes with manual operation will be provided as part of standard sprayer equipment. Brakes with automatic operation will also be available as optional equipment.

Optionally, the sprayer can be equipped with a turning axle. The turning axle ensures that the sprayer continuously and accurately follows the tractor’s wheel track. This reduces the trampling and damage to the crops. It will be possible to choose between versions with or without the turning axle. The turning axle is only available in combination with air springs and ISOBUS system.

Designed with the user in mind, the AGS 3600 – 4200 HP sprayer is equipped with a suspension system. The air suspension system enables stable and comfortable driving on rough terrains and roads. As standard, the sprayer is fitted with rubber dampers but it can also be optionally fitted with an air suspension system.

It combines a well-arranged control panel, a step-on platform for accessing the lid of the main tank, a filling container and a pressure valve for adjusting the mixing pressure – all in one place. The control panel enables easy and quick operation of the sprayer. It includes all the systems (operation, cleaning, pumping, suction and filling) required to operate the sprayer's support functions.

The HPX boom series with working widths between 21 and 24 m and the TR4 booms with working widths between 27 and 30 m allow for single-sided spraying, levelling and adjustment to low spraying heights.

The aluminium booms also allow for single-sided levelling. They automatically adjust to the task at hand – spraying. The modern structural design of the booms enable virtually automatic adaptation to the terrain without the need for manual adjustment.

These booms feature stainless steel or aluminium spraying pipes. Hydraulic opening, lifting and levelling operations are controlled from a convenient control panel or the ISOBUS monitor.

They are equipped with a safety system which prevents them from closing when in working position and a mechanism for automatic locking in the transport position. The booms are mounted on a two-point hitch which enables terrain copying, even on sloping terrains.

The hydraulic accumulator is provided for vertical shock absorption, while rubber dampers protect the sprayer from damages due to impacts coming from other directions. The boom arms are folded laterally, next to the tank, to ensure compact transport dimensions. The parallelogram mechanism allows the boom to be lifted up to a height of 230 cm to reach the higher-growing crops (corn, sunflowers, tobacco).

The HPX boom series with working widths between 21 and 24 m and the TR4 booms with working widths between 27 and 30 m allow for single-sided spraying, levelling and adjustment to low spraying heights.

The aluminium booms also allow for single-sided levelling. They automatically adjust to the task at hand – spraying. The modern structural design of the booms enable virtually automatic adaptation to the terrain without the need for manual adjustment.

These booms feature stainless steel or aluminium spraying pipes. Hydraulic opening, lifting and levelling operations are controlled from a convenient control panel or the ISOBUS monitor.

They are equipped with a safety system which prevents them from closing when in working position and a mechanism for automatic locking in the transport position. The booms are mounted on a two-point hitch which enables terrain copying, even on sloping terrains.

The hydraulic accumulator is provided for vertical shock absorption, while rubber dampers protect the sprayer from damages due to impacts coming from other directions. The boom arms are folded laterally, next to the tank, to ensure compact transport dimensions. The parallelogram mechanism allows the boom to be lifted up to a height of 230 cm to reach the higher-growing crops (corn, sunflowers, tobacco).

The spray boom sets are fitted with Agromehanika TRI-JET nozzle holders with integrated nozzle inserts by a renowned German manufacturer Lechler. TRI-JET nozzle holders feature three integrated nozzle inserts, designed for spraying different crops.

Agromehanika TRI-JET nozzle holders are equipped with an anti-drip diaphragm valve to prevent unwanted dripping from the nozzles.

For safe driving on public roads.

The sprayer is equipped with two reflective boards, rear lights with a reflective triangle and two white reflectors installed on the boom set.

Thanks to the control panel, the boom set can be controlled from the tractor cab. It is operated by the electro-hydraulic manifold mounted on the boom set.

The hydraulic system is used to control lifting, levelling or terrain following, locking and individual opening of the left or the right boom.

Thanks to the control panel, the boom set can be controlled from the tractor cab. It is operated by the electro-hydraulic manifold mounted on the boom set.

The hydraulic system is used to control lifting, levelling or terrain following, locking and individual opening of the left or the right boom.

The ISOBUS spraying computer includes one connector that can be used to connect different machines with an integrated ISOBUS system, regardless of the brand. The system is equipped with a 9pin socket for connecting various implements. The system can be connected to any computer that supports the ISOBUS system, Thanks to this computer, you can focus on safe driving without having to look back and forth to watch the rear of the machine. In addition to computer connectivity, the ISOBUS electronic system also allows you to connect with the navigation system, which lets you know exactly which areas have already been treated. The ISOBUS system provides for an easy connection of other tractor implements, such as seeders, spreaders etc.

The sprayer’s ISOBUS system can be used to operate all hydraulic features of the sprayer.

Fully automated spraying. In combination with AG-TRONIK S1 spraying computer, the navigation system ensures automatic operation of the spraying sections and it provides a better overview and more control over your work. Unlike the classic marker, this system can also be used at night. Spraying with the GPS navigation system is also easier, more precise and faster. It enables saving the work history and operating parameters. It also features parallel guidance and allows for entering obstacles or positions of spraying interruption.

It regulates the flow rate required for accurate spraying through flow rate and speed sensors, based on the desired spray volume per hectare. When the spraying sections are individually closed, the AG-TRONIK S1 immediately adjusts the amount of the plant protection product. The system is intuitive and easy to use. Additionally, the AG-TRONIK S1 also allows you to analyse and save your work and to transfer data via USB cable. Just enter the desired spray volume and start spraying.

The basic AGS 3600-4200 HP sprayer version includes the 300/95R46 (3600 L tank) and 340/85R46 wheels (4200 L tank). The 340/85R48 and 380/90/R46 are also available as an option.

We recommend cleaning the exterior of the machine after each spraying. This ensures uninterrupted operation of the machine by removing the residues of the aggressive chemicals. The kit consists of the self-winding hose reel and a high-performance spraying lance.

For safe and efficient night spraying, we equip your boom set with LED lights.

We can also equip your sprayer with work lights.